IMPELLERS

SWSTech has a team of experts in the field of impeller and blisk manufacturing. SWSTech is a manufacturer of a large variety of impellers. Apart from the machinery on the premises we offer a wide selection of services and expertise in the field of consulting and nc-programming:

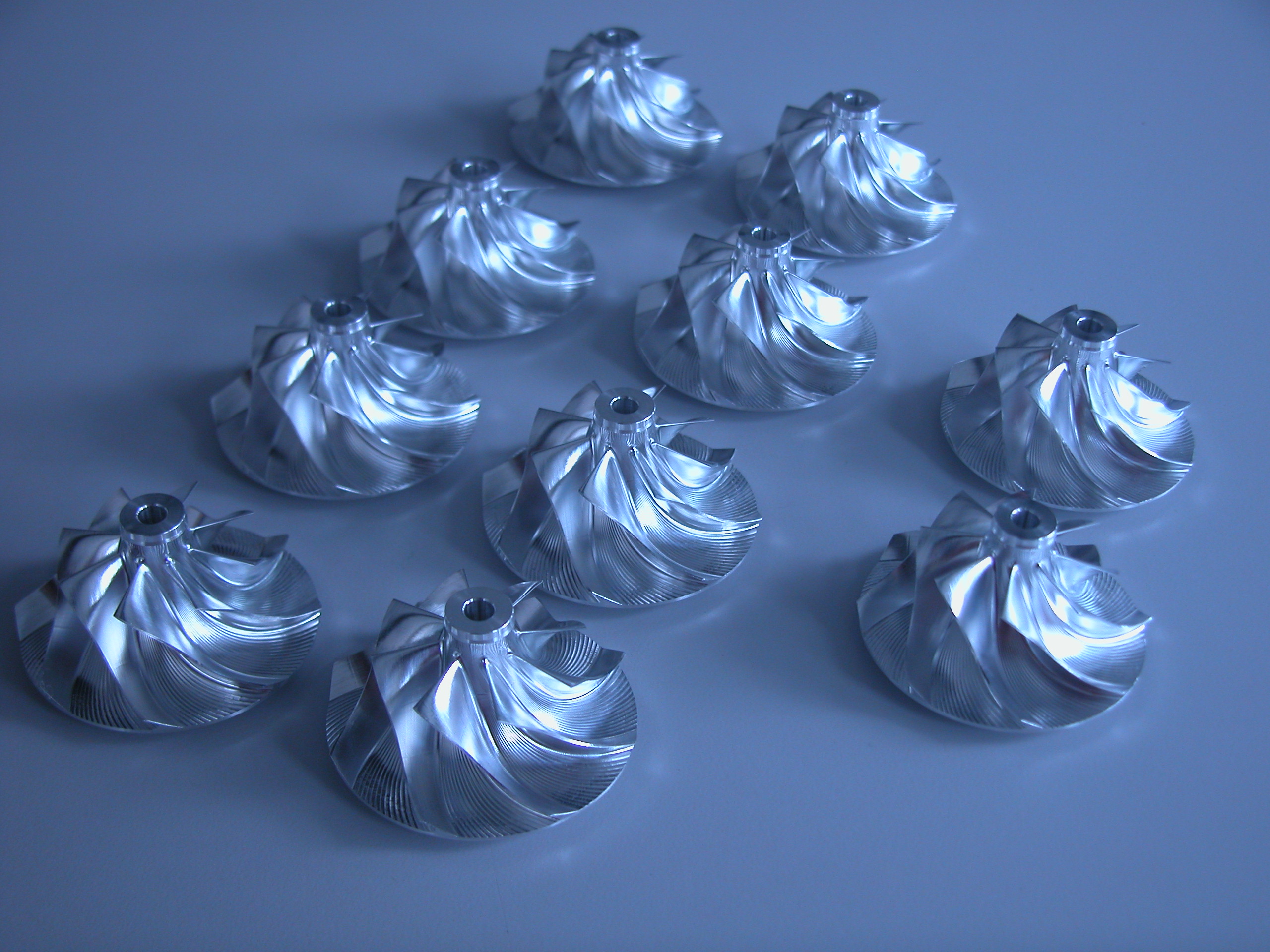

Open Impeller

Machining with flank-contact for ruled surfaces or point-milling for arbitary surfaces.

Time calculations and process optimization.

Closed Impeller

Milled out of one block for maximal strength.

No matter what material – we have a wide range of tool and strategy-knowledge to get the most economic process.

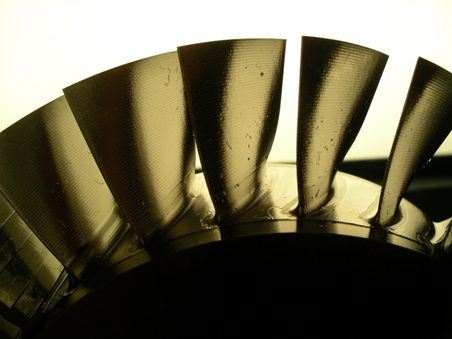

Blisks / Blings

Bladed disks (Blisks) and blades rings (Blings) as well as single blade machining.

Prototypes / Series

No matter on the batch size – we will realize your prototype series.

Manufacturing of open impellers and blisks (bladed discs)

- Flank milling of the blades (ruled surfaces)

- Point milling of arbitrary surface blades

- Access from the shroud or from inlet and outlet (side-entry-milling)

Manufacturing of shrouded impellers or blings (bladed rings):

- Open milling and brazing

- Open milling and welding

- Integral milling by side entry access

Size range:

- 5mm < Diameter <= 1000mm, larger diameters on request.

We develop the milling processes e.g. for the following materials

- aluminum alloys

- steel

- stainless steel

- titanium

- nickel-/cobalt- based alloys

Based on the extended knowledge of tools and strategies we can carry out various optimizations

- Cycle time optimization

- Maximum process stability

- Tool cost reduction

Furhtermore, we are using effective strategies

- Tool and material dependent HSC-strategies

- Plunging

- Trochoidal milling

- Optimization of material removal

- Special cutters

To be able to program with the best strategy, customer data are adapted to the process requirements if necessary.

We use ConceptsNREC MAX-PAC impeller milling software and CGTech Vericut® for simulation and optimization.

The SWSTech postprocessor translates the NC-data into machine-specific G-code.